- Home Page

- Company Profile

-

Our Products

- Automotive Tyres

- Taishan Agricultural Tractor Tire/Tyre

- Wholesale Factory Truck Radial Commercial Car Tubeless Tyre

- Top grade PCR Passenger Car Tire

- New Quality PCR Passenger Car Tire

- High quality Truck/Bus Tyre for sale

- PCR Car Tyres

- TBR Truck And Bus Tyres

- Taisha Tractor Tyres

- Agricultural Tractor Tyres

- Top grade Agricultural Tyre Tractor Tire

- Excellent Car Tyres

- Quality Car Tyres for Sale

- Brand New PCR Tyres

- Top Grade Car Tyres

- New TBR Tyres

- High Performance TBR Tyres

- Solid Truck and Bus Tyres for sale

- Replica Deer Antlers

- Edible Oil

- Top Grade Sunflower oil

- CP10 Palm Oil

- Pure Virgin Sesame Oil

- 3L RBD Canola Oil

- Pure Soyabean Oil

- Virgin Sesame oil

- Purely top grade Virgin Sesame oil

- Top grade Sesame Virgin oil

- High value Sesame Refined Oil

- Grade A Virgine Sesame Oil

- Top Quality Sunflower oil

- Good Quality Sunflower oil

- Purely Refined Sunflower oil

- RBD Canola oil

- Top 100% Canola oil

- RBD Rapeseed/Canola Oil

- Original Refined RBD Canola oil

- Purity OEM Refined Canola oil

- Engine Oil

- HDPE Granules

- Industrial Scrap

- PAPER OCC (OLD CORRUGATED CARDBOARD - CARTON)

- Wholesale OCC Waste Scrap Paper Best Price

- Top Quality OCC Waste Paper /OCC 11 and OCC 12

- OCC WASTE PAPER FOR RECYCLING

- Top quality scrap tyres

- PCR and TBR Tyre Scrap

- Good Quality Tyre Scrap

- CPU Scrap

- OCC Waste Scrap

- Tire Scrap

- UBC Scrap

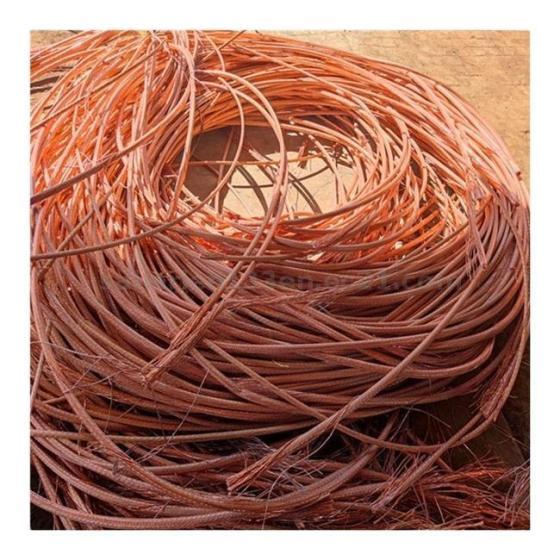

- High Quality Copper Wire Scrap 99.9%/Millberry Copper Scrap 99.99%

- Purely Copper Scrap 99.99% Purity

- Grade A Copper Wire Scrap

- High Purity Copper Wire Scrap

- Super High Quality Copper Wire Scrap 99.9%/Millberry

- Pure Copper Mill Berry Scrap 99.99%

- LDPE Film

- Milk Powder

- Tissue Paper Jumbo Roll

- Agriculture Product

- Certified 1121 Basmati Golden Sella Rice

- OEM Basmati rice

- Long Grain Basmati Rice 1121 / Pusa Steam Basmati Rice

- Organic Basmati Rice

- Premium Red and Yellow Onions

- Top grade White and Yellow Onions

- Dried Yellow and Red Onions available

- Wholesale Yellow and Red Onions available

- Red and Yellow Onions

- Peanut Kernels Round Shape

- Fresh Peanuts Kernels available

- Top grade Peanuts Kernels

- Good Quality Peanuts Kernels

- Red and Yellow Onions

- Medical Equipment

- Multifunctional Electric Hospital Bed 5 Functions ICU

- ICUElectro control Hospital Bed

- Clinic Furniture Electric 5 Functions ICU

- Medical Patient Nursing Hospital Bed

- Electric Power Scooter Wheelchair

- Cheapest Steel Wheelchair Used in Hospital

- Foldable Electronic Wheelchairs

- High Quality Hospital Wheelchairs

- Electro control Hospital Bed

- mounjaro tirzepatide

- Chemicals

- Household products

- Office Paper Roll

- Double A4 Paper 80GSM

- Double A Copy Paper A4 80 gsm, 75 gsm, 70 gsm 500 sheets

- High Grade Double A4 Paper

- Top Quality A4 Copy Paper

- Quality Jumbo Thermal Paper Roll

- High Grade Thermal Paper roll

- Jumbo Thermal Paper roll

- OEM Printed Cash Register Roll Jumbo Rolls Therma Paper

- Therma Paper Till Self Adhesive Sticker Labels

- Therma Paper Sticker Labels Rolls

- High Quality Thermal Paper

- Good Grade Thermal Paper Roll

- Best Thermal Paper Roll

- PBS Granules

- Corrugated Carton Boxes

- Wood

- Automotive Tyres

- Contact Us

High Purity Copper Wire Scrap

3850 USD ($)/Metric Ton

Product Details:

- Condition Scrap

- Scrap Type Copper Wire Scrap 99.9%/Millberry

- Grade 99.99%

- Purity 99.99%

- Composition 100% recycled material.

- Color RED

- Click to view more

X

High Purity Copper Wire Scrap Price And Quantity

- 3500.00 - 3850.00 USD ($)/Metric Ton

- 3850 USD ($)/Metric Ton

- 1 Metric Ton

High Purity Copper Wire Scrap Product Specifications

- Copper Wire Scrap 99.9%/Millberry

- 100% recycled material.

- Scrap

- 99.99%

- RED

- 99.99%

High Purity Copper Wire Scrap Trade Information

- Laem Chabang Port

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- 5000 Metric Ton Per Month

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- Wooden Box

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- CE ISO

Product Description

Model NO.: customized

Material: Brass

Shape: Coil

Alloy: Alloy

Color: Red

Standard: ASTM GB/T JIS En ISO

Keyword: Copper Wire Scrap

MOQ: 1ton

Sample: Supply

Packaging: Wooden Box

Transport Package: Standard Airworthiness

Specification: Customizable

Origin: Thailand

Production Capacity: 5000 Tons Per Month

Exceptional Purity for Industrial Applications

This copper wire scrap stands out with a remarkable 99.99% purity level, ensuring optimal efficiency in remelting and manufacturing processes. Its condition as clean, bright, and red Millberry scrap makes it highly sought-after by industries requiring superior electrical conductivity and performance. Sourced and processed in Thailand, each batch reflects our dedication to quality assurance.

Versatile Uses in Diverse Sectors

High Purity Copper Wire Scrap is indispensable in various sectors, including electronics, cable manufacturing, and construction. With its reliable composition, it is a preferred material for recycling into new copper products. Its high electrical and thermal conductivity makes it suitable for wiring, bus bars, and other components requiring refined copper input.

FAQ's of High Purity Copper Wire Scrap:

Q: How is the High Purity Copper Wire Scrap processed?

A: The scrap is sourced from post-consumer copper wire, thoroughly cleaned and sorted to ensure only high-purity materials are included. It then undergoes a rigorous inspection process to confirm the 99.99% purity grade before packaging and shipment.Q: What are the primary uses for this copper wire scrap?

A: This scrap is widely used in the manufacturing of electrical cables, wires, electronic components, and recycled copper products. Its excellent conductivity and purity make it suitable for industries requiring premium raw materials.Q: Where is your High Purity Copper Wire Scrap sourced and supplied from?

A: We operate from Thailand, serving as a distributor, exporter, manufacturer, supplier, and trader. Our copper scrap is processed locally and distributed both within Thailand and internationally.Q: When is the best time to use copper wire scrap in manufacturing?

A: Copper wire scrap can be used at any phase of production where refined copper input is required, notably during remelting operations, component manufacturing, or when cost-effective raw copper supplies are needed.Q: What benefits does using 99.99% pure copper scrap offer?

A: Utilizing copper scrap of such high purity ensures reliable conductivity, enhances the quality of finished products, reduces environmental impact by supporting recycling, and often lowers production costs compared to using newly mined copper.Q: How does purchasing from a Thai supplier impact quality and supply?

A: Choosing us as your Thai supplier ensures a consistent supply chain, strict adherence to international quality standards, and competitive pricing due to Thailand's robust copper recycling industry.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email